SRS-660BI Carbon Fiber – Bidirectional 660 GSM FRP Strengthening System for Structural Concrete

The SRS-660BI Carbon Fiber System is a high-strength, bidirectional 660 gsm CFRP fabric engineered for structural strengthening and rehabilitation of concrete, masonry, and timber elements. With a balanced 0°/90° fiber orientation, high tensile capacity, and predictable performance, SRS-660BI is ideal for both engineered FRP strengthening designs and contractor-installed reinforcement applications. Typical uses include slab strengthening, shear wall upgrades, punching shear reinforcement, and restoration of deteriorated structural members.

SRS-660BI bonds externally to structural members using SRS-1000 Structural Epoxy Resin, forming a composite system that increases load-carrying capacity, enhances shear and flexural performance, and improves the long-term serviceability of concrete structures. The system is commonly used in commercial, industrial, municipal, and residential structural repair projects requiring reliable, low-profile reinforcement.

Need stamped engineering design, FRP layout drawings, or project-specific calculations?

Our engineering team provides CFRP design support, repair details, and submittal packages.

Structural Confinement of Concrete Block Support Columns on an emergency telecommunications tower in the Florida Keys

Repairing the concrete and reinforcing the edges and openings of tank lids with SRS-660BI to provide crack confinement

Applying SRS 660 Bi-Directional carbon fiber to a cracked foundation stem wall to reinstate structural capacity and seismic resilience in California.

Structural Confinement of Concrete Block Support Columns on an emergency telecommunications tower in the Florida Keys

Applications

The SRS-660BI Carbon Fiber system is used in a wide range of structural strengthening projects involving concrete, masonry, wood, and select steel components. Designed for compatibility with epoxy-based FRP systems, it is commonly used in:

Structural Strengthening

-

Increase flexural capacity of slabs, decks, and joists

-

Strengthen elevated parking structures and floor systems

-

Provide bidirectional reinforcement for multi-directional load demands

-

Reinforce deteriorated or under-reinforced concrete members

Shear & Crack Control

-

Improve shear resistance on beams, walls, and slab-column connections

-

Limit crack propagation in concrete or masonry elements

-

Provide multidirectional crack stabilization before overlays or repairs

Slab & Punching Shear Reinforcement

-

Upgrade punching shear resistance around concrete columns

-

Improve slab performance where two-way strengthening is required

-

Enhance load distribution using balanced 0°/90° reinforcement

Column, Pier & Wall Strengthening

-

Bidirectional wrapping for confinement, ductility, and shear enhancement

-

Improve axial performance of columns, piers, and pilasters

-

Strengthen retaining walls, shear walls, and basement walls

Rehabilitation & Restoration

-

Extend service life of aging or deteriorated concrete structures

-

Strengthen corroded, cracked, or impact-damaged members

-

Reinforce structures for change-of-use, added loads, or retrofit upgrades

Features & Benefits

High-Strength Bidirectional Reinforcement

660 gsm carbon fiber fabric providing balanced 0°/90° reinforcement for shear, flexural, and crack stabilization applications.

Lightweight, Low-Profile Installation

Delivers significant strength improvements without adding bulk or altering existing structural dimensions.

Corrosion-Proof Composite System

Non-corrosive carbon fiber and epoxy system designed for long-term durability in harsh or moisture-prone environments.

Compatible with SRS-1000 Epoxy Resin

Engineered for proper wet-out, bond performance, and consistent adhesion on concrete and masonry surfaces.

Versatile Application Options

Suitable for structural slabs, beams, walls, columns, piers, and punching shear reinforcement around supports.

Fast Installation with Minimal Downtime

Applies efficiently to vertical, horizontal, and overhead surfaces, improving productivity and reducing project delays.

Balanced Fiber Architecture

Bidirectional fiber layout delivers predictable load improvement and reliable performance across multiple stress directions.

Specifications

The strengthening system shall consist of a high-strength, bidirectional carbon fiber fabric with a nominal areal weight of 660 gsm, installed using a compatible epoxy saturant/adhesive.

The installed composite shall meet or exceed the following minimum properties:

-

Tensile Strength: 711 ksi (4,900 MPa)

-

Tensile Modulus: 33.4 Msi (230 GPa)

-

Design Laminate Tensile Strength: 164,300 psi (1,133 MPa)

-

Ultimate Laminate Tensile Strength: 196,000 psi (1,352 MPa)

-

Elongation at Break: 2.10% (fiber), ~2% (laminate)

-

Laminate Ply Thickness: 0.018 in (0.46 mm)

-

Fiber Orientation: 0°/90° bidirectional load paths

-

Fabric Type: Bidirectional, dry CFRP fabric

The CFRP strengthening product shall be SRS-660BI Carbon Fiber as manufactured by Structural Reinforcement Solutions, Thornville, Ohio.

Installation Overiew

The SRS-660BI Carbon Fiber System is installed using a field-saturated wet-layup process with SRS-1000 Structural Epoxy Resin. Proper surface preparation and installation procedures are essential for achieving full composite performance.

-

Surface Preparation

Concrete surfaces must be clean, structurally sound, and properly prepared. All weak or debonded material, coatings, and surface contaminants must be removed. Spalls, cracks, and deteriorated concrete shall be repaired prior to CFRP installation.

-

Primer & Saturant Application

Apply SRS primer (if required) followed by a uniform layer of SRS-1000 Epoxy Resin. The epoxy serves as the bonding medium between the substrate and the carbon fiber fabric.

-

Fabric Placement

Place the SRS-660BI bidirectional carbon fiber onto the wet epoxy and work the material into the resin to ensure full saturation and contact with the substrate. Install additional epoxy as needed to achieve complete wet-out.

-

Final Resin Coat

Apply a final coat of SRS-1000 Epoxy over the exposed fabric to encapsulate the fibers and provide proper composite formation.

-

Curing & Quality Control

Allow the system to cure according to SRS guidelines. Inspect the installed laminate for air pockets, wrinkles, dry spots, or misalignment. All work should follow SRS installation instructions and project-specific engineering requirements.

Storage & Shelf Life

Store all CFRP materials in a dry, covered area between 40°F and 95°F (4°C to 35°C). Protect carbon fiber fabric and epoxy from moisture, dust, and direct sunlight. Keep products in their original, unopened containers until use.

Carbon fiber fabric has a shelf life of 10 years when properly stored.

SRS-1000 Structural Epoxy Resin has a shelf life of 2 years in unopened containers.

Do not allow materials to freeze. Always follow SRS product guidelines and project specifications for handling and storage requirements.

Case Studies

Parking Garage

Wall Reinforcement

Brick Column

Strengthening

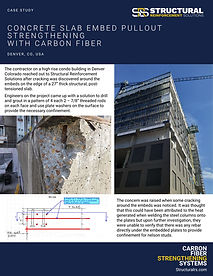

Slab Embed

Pullout Strengthening

Retaining Wall

Reinforcement